Exploring the Composition of Credit Cards: Materials and Construction

Credit cards have become an integral part of modern financial transactions, offering convenience and security to consumers worldwide. Have you ever wondered what goes into making these seemingly simple yet sophisticated pieces of plastic? In this article, we will delve into the composition of credit cards, exploring the materials used and the construction process that transforms them into the versatile payment tools we use every day.

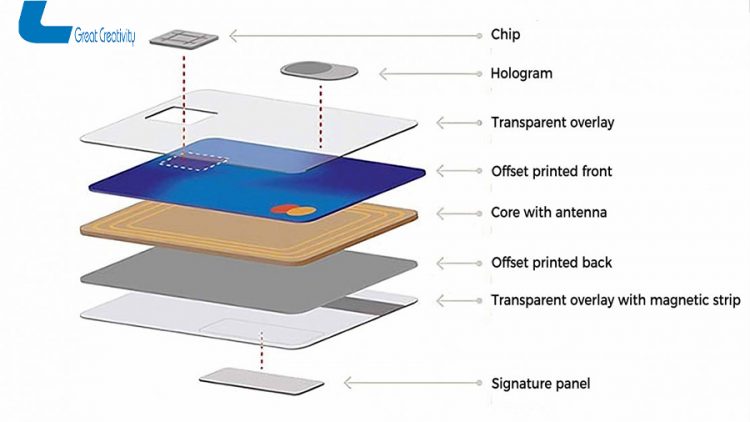

The Anatomy of a Credit Card

Credit cards might appear to be straightforward, but they are carefully engineered to balance durability, security, and functionality. A standard credit card consists of several layers, each serving a specific purpose.

- Core Layer: The core layer forms the base of the credit card. It is typically made of PVC (polyvinyl chloride), a strong and durable plastic. PVC provides the card’s rigidity and thickness. This layer is often referred to as the “card body.”

- Printed Design Layer: Above the core layer lies the printed design. This layer includes the cardholder’s name, account number, expiration date, and the issuing bank’s logo. It’s printed using a combination of technologies, including offset printing and digital printing.

- Overlay Layer: To protect the printed design and enhance the card’s durability, an overlay layer is applied. This layer is usually made of clear PVC or another protective material. It helps prevent wear and tear, including fading of the printed information.

- Magnetic Stripe or Chip Layer: Most credit cards feature either a magnetic stripe or an embedded microchip. The magnetic stripe contains the card’s account information in a format that can be read by magnetic card readers. The chip, also known as an EMV chip, provides enhanced security by generating unique transaction codes for each use.

- Signature Panel: A signature panel is often found on the back of credit cards. It’s a white strip that allows cardholders to sign their names, providing an extra layer of authentication during transactions.

Materials Used in Credit Card Production

- Polyvinyl Chloride (PVC): PVC is the primary material used for the core layer of credit cards. It’s favored for its strength, durability, and cost-effectiveness. However, concerns about environmental impact have led some manufacturers to explore more sustainable alternatives.

- PETG (Polyethylene Terephthalate Glycol): Some credit card manufacturers have started using PETG as an eco-friendly alternative to traditional PVC. PETG is a type of polyester plastic that offers similar strength and durability while being more environmentally friendly.

- Holographic Foils and Films: Holographic elements, such as foils and films, are often added to credit cards to enhance security and aesthetics. They create a distinctive visual effect that is difficult to replicate, deterring counterfeiting attempts.

- Metallic Inks and Special Pigments: Metallic inks and pigments are used to print certain design elements on credit cards. These inks can create a reflective, shiny appearance that adds a premium feel to the card.

Conclusion

Credit cards are more than just pieces of plastic; they are carefully crafted financial tools that combine various materials to ensure durability, security, and functionality. The intricate layers of PVC, PETG, magnetic stripes, chips, and holographic elements work together to create a payment method that has revolutionized the way we conduct transactions. As technology continues to evolve and environmental considerations gain prominence, the materials and methods used in credit card production are likely to undergo further innovations, making these small plastic cards even more resilient and sustainable in the future.

Shelley

Shelley Nielsen

Nielsen